【Origin Pic】 |

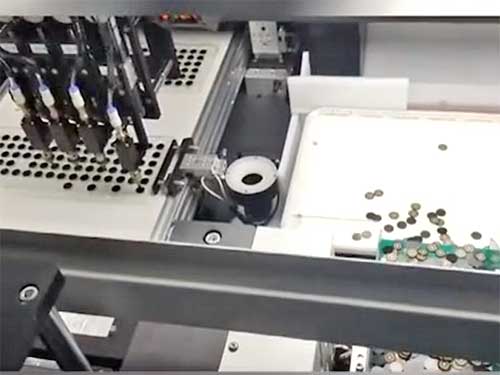

Tray Placement Machine TP-0001 The equipment adopts a flexible feeding method, and the output is tray/ plastic pallet/ fixture tray. Feeding - Manual pouring of loose materials into the hopper. Recognition - CCD above the flexible vibrating disk recognizes the materials' front and back sides, angles, and calculates their coordinates. Pick-up and transfer - The robotic arm grabs the successfully recognized materials and adjusts the chip's angle during the transfer process. Placement - The robotic arm moves to the tray placement position and places the materials one by one into the target cavities of the target tray. Reinspection - The CCD reinspection station performs a second inspection of the material's orientation before packaging. If OK, it proceeds to packaging. If NG, it is manually processed at the NG processing station. Tray stacking - Sequentially repeating the process.

|

中文版

中文版 英文版

英文版