【Origin Pic】 |

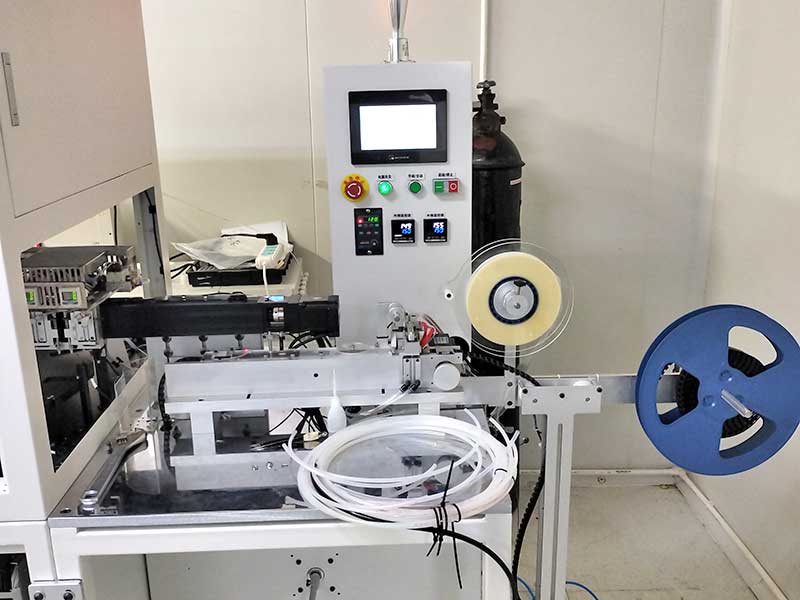

Reel to Reel Automatic Taping Machine RTR-100 The The equipment utilizes a pneumatic robotic arm structure to facilitate the process of unloading materials from the reel and transferring them to an intermediate workstation for resealing. The intermediate workstation can be customized to fulfill various functions based on customer requirements, such as appearance inspection, functional testing, electrical testing, laser marking, counting, and more.

|

中文版

中文版 英文版

英文版